Your CDMO partner for liquid challenges –

from IDEA to MARKET-READY solution

Contract Development & Manufacturing Partner for Advanced Liquid Solutions.

From formulation to full-scale production – compliant, precise, and flexible.

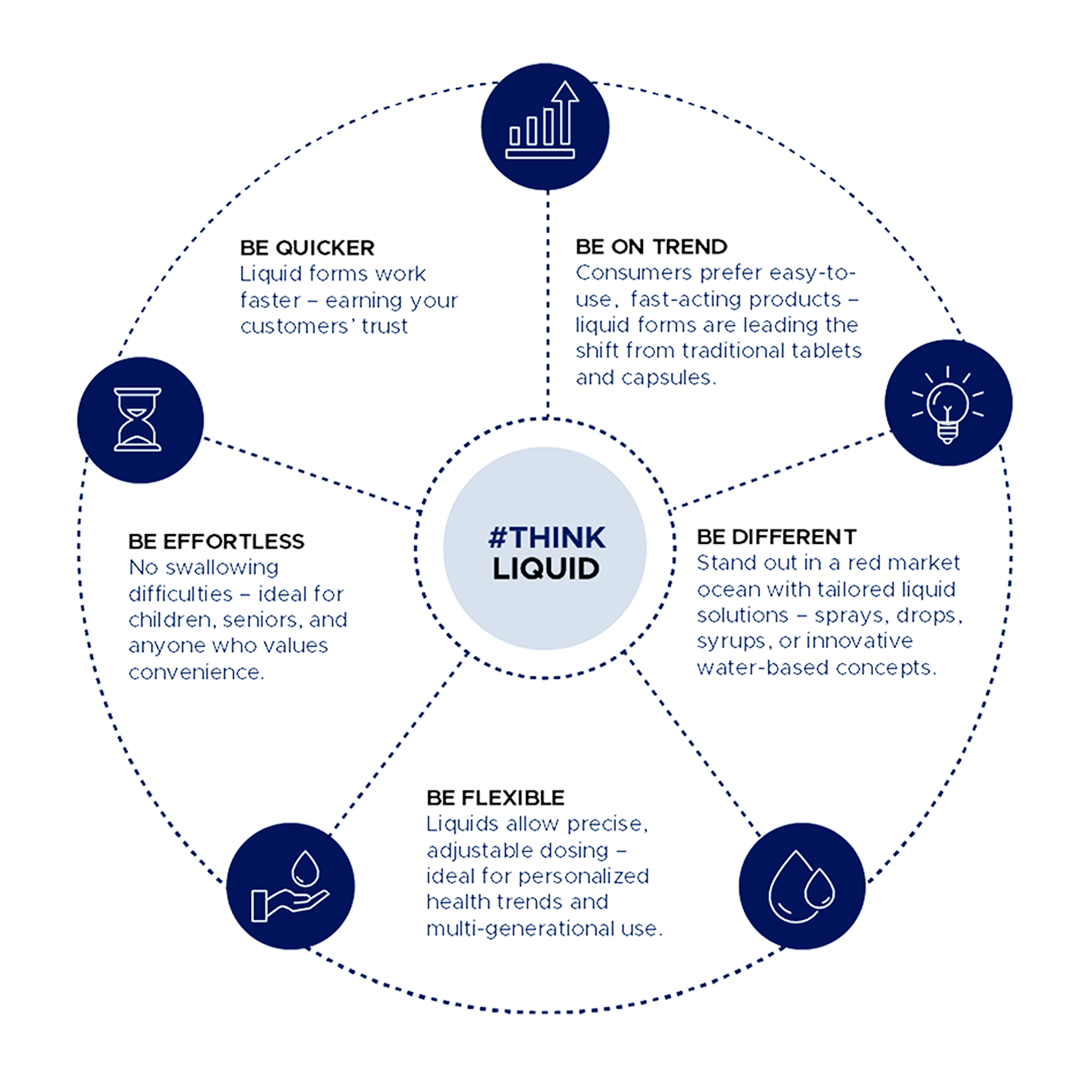

#THINK LIQUID

YOU BRING THE IDEA

we shape the formula, the format, and the final product

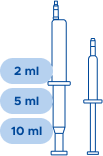

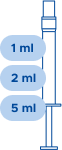

LIQUID

FORMATS

LIQUID FACTS

50% PATIENTS

with chronic conditions do not take their tablet medications as prescribed

11-14 % CAGR

liquid dietary supplements

56 -67% RESPONDENTS

consider liquid forms as comfortable to use

20-40% FASTER

absorption observed for liquid formulations compared to tablets.

10-34% RESPONDENTS

of surveys experience anxiety about swallowing tablets

CONTACT US

ANNA DUDEK

Business Development Manager